3D Print a Snap-Fit Piece

I was recently tasked with outfitting and organizing a brand new mechanical assembly room at work. I picked up a Husky garage tool rack from Home Depot to hang up hand tools. It looks like this.

They offer a number of accessories to go with it, including hooks and a rack with square holes in it. This would be great for hanging all sorts of drivers if the openings weren’t so large. I set out to print out some reducing adapters.

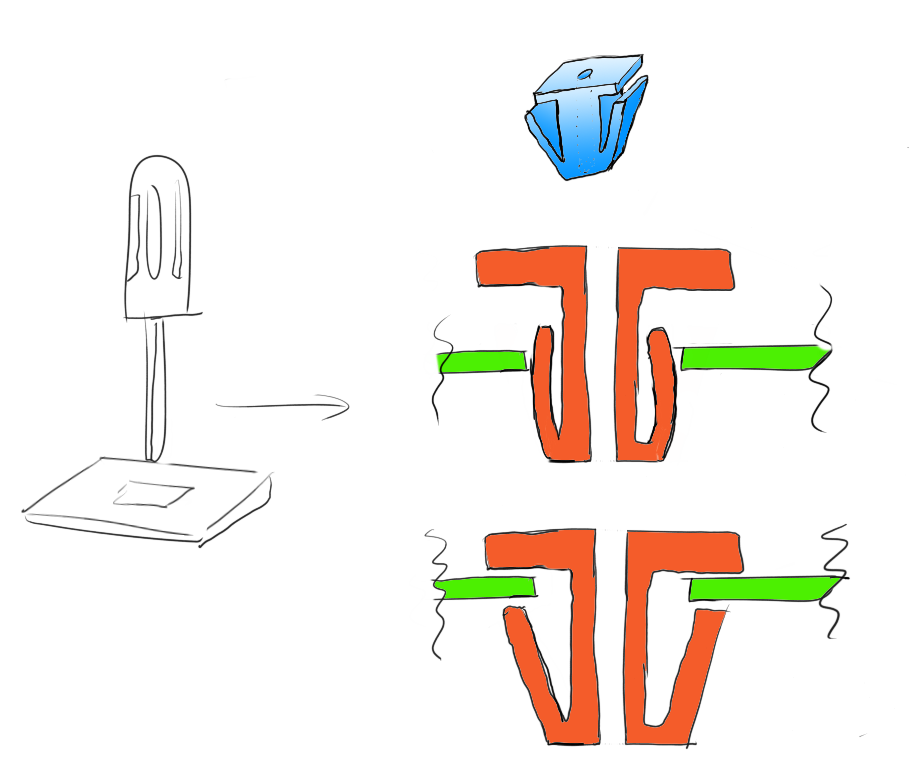

Concept

My idea is simple: make a snap-fit “adapter” that sits on (and locks itself within) a square opening, but exposes a much smaller opening for flat, cross, and hex drivers. I have worked with enough FDM pieces to know that there is quite a bit of give with printed ABS, so a “snap-fit” piece will not be particularly challenging. The geometry will only require the following features:

- A base for the head of the driver

- Two “flaps” that lock against the bottom of the rack.

- A channel for the driver that will also serve as a pilot hole if I need to drill it open.

Reducing Adapter MKI

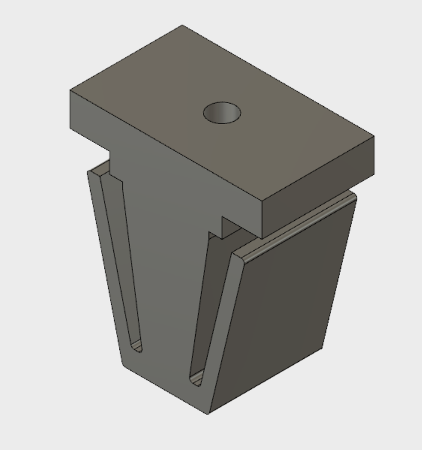

The first model looks like this in Fusion 360:

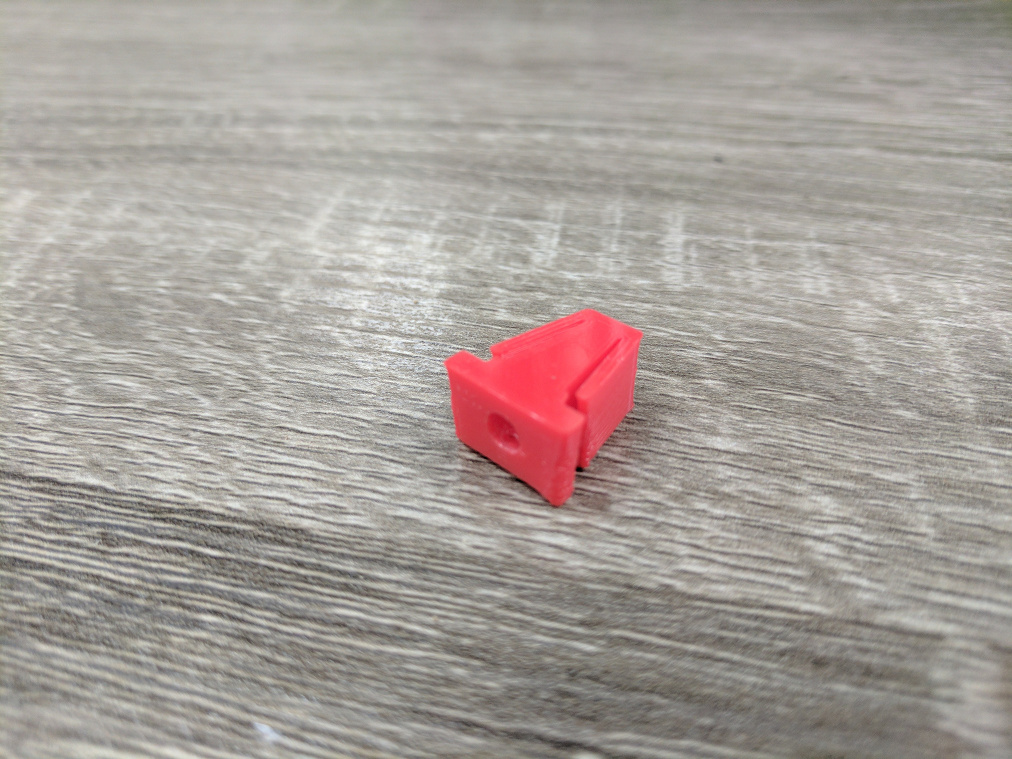

Using SolidWorks Simulation I confirm that it will take under 10N to flex both tabs all the way in. So, after ten minutes on the MakerBot at Newmakeit I end up with this:

The tabs do the job alright, but I left a bit too much clearance against the square shape so the whole thing rattles a bit much.

Reducing Adapter MKII

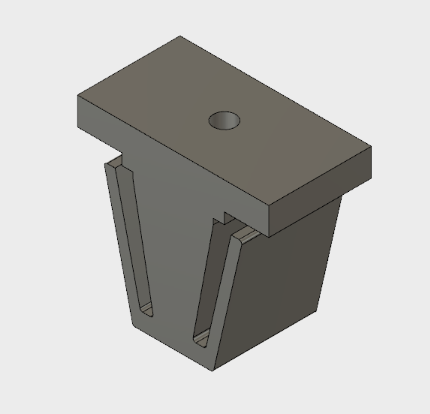

The second model is only a bit wider, and the spacing for the rack sheet metal goes down from 1.5mm to 1mm:

This is what the piece looks like on the tool rack:

It’s a much better fit now.

Lessons learned

You can easily make snap-fit pieces using hobby-grade 3D printers. You just have to experiment :)

Questions? Comments? Give me a shout!